This post is for engineers, techies, farmers, and renewable energy enthusiasts. Think of it as a Discovery Channel program on your computer. Except no commercials. And well, lower quality. But more jokes. And short "sentences". Like this.

But in this post I want to tell you about something hopeful (for a change) going on in Honduras. I want to tell you about something widespread, metaphorically and literally green, and economically beneficial on a large scale. I want to tell you about something that will make you feel good on account of it being so clever. Think of it as the feel-good hit of the summer, or at least as you're good as you're going to feel reading this blog.

OK, here we go.

The African Palm industry is the second largest industry in the country of Honduras. African Palms are a class of trees known as "oil palms", and they produce "palm oil" which is, of course, a type of vegetable oil. Palmolive: softens hands while you do the dishes. The main use for palm oil is cooking, and Honduras is exporting it to the tune of $350,000,000 to $450,000,000 per year. Only coffee can claim higher numbers.

It's funny, because oil palms produce palm oil. It's like an agricultural palindrome. Except it's the words that are reversed, not the letters. I suppose it would be closer to being a real palindrome if oil palms produced smlap lio, but they don't, so that's as close as we're going to get. But you already understand that, so let's move on.

[a truck collects palm fruit on an access road in a plantation of African Palms]

As you drive around the bread basket of Honduras, the Sula Valle, you will see miles and miles (kilometers and kilometers) of these palms in giant plantations. You will see them in different stages of development, since they live for more than 30 years. Those that are less than five or ten years old are only bushy adolescents and don't produce much fruit yet, but as they age they get taller and start producing large clusters of palm fruit that are chopped from the tops of the trees by men with long sleeves and longer poles, the ends of which have a curved saw like a tree trimmer's tool. In the mornings and afternoons, you will see them riding their bikes back and forth to work with their 20 foot pole saws balanced on their shoulders. Other workers gather these clusters and throw them into trucks with pitch forks.

The fruit comes in clusters like giant grapes that remind me of the story of Joshua and Caleb coming back from spying out the promised land. The clusters are called "raquis" pronounced rah-keys. Kinda like Iraqis without the I. They weigh up to 50 pounds - the raquis that is, not Iraqis. Can you imagine what a commotion they make when the come falling down from the tops of the trees? Stand aside, Clyde, or be killed by a falling vegetable. The raquis of fruit sell for between $1000-$1100 per ton.

[These are raquis, or clusters, of palm fruit. On the right are a few big ones in a wheel barrow.]

The fruit itself is a woody date-like thing about the size of an oblong golf ball. There are over 100 "palmas", or fruits, in a raqui. I don't know how many are in Iraqi. I asked some experts what they were called. It wen't like this:

Me: What is the name of the actual fruit part?

Expert: It's called a "palma".

Me: I thought "palma" was what they called the whole tree?

Expert: It is. The tree is called a palma and so is the fruit. Palmas arboles y palmas frutas.

Me: I understand it softens hands while you do the dishes?

[a palma in the palma is worth two in the bush]

[When you slice open a palma, you can see three distinct parts. The orange outer part is called the pulp (pulpa) and is 21% oil. The oil that comes from this part is called crude (crudo) oil and is the type used for cooking. The brown ring that surrounds the white part is a hard nut (nuez) and the inside is known as the almond (almendra). The almond is only 1% oil. This tiny bit of oil is called kernel (palmiste) oil and is also extracted and used for soaps and cosmetics. Both types of oils are exported to Europe, the USA, and Mexico.]

I had the honor of getting to tour an excellent plant that extracts the oils from the fruit. The name of the plant was Palcasa. Perhaps "Palcasa" is a contraction of palma casa, or house of palms, sorta? "Palm House... in the middle of our street."

At any rate, this plant is one of a dozen large plants in Honduras and produces about 10% of the country's output. This particular plant has won environmental awards because of the way they use their waste streams to produce energy, and that is why I am writing about it.

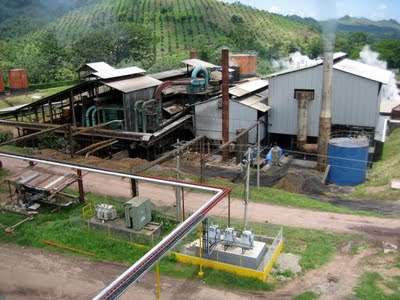

[The Palcasa plant for extracting oil from African Palms]

[You can see small, medium, and large trucks unloading raquis of palmas into large reddish brown piles. The processing plant is owned by over 1000 farmers in a coop and it processes about 60 tons per hour.]

[The first step to extracting the palm oil: Raquis are queued up in giant hoppers and get dispensed into carts mounted on railroad tracks.]

[The carts are rolled into steaming chambers where the fruit becomes sterilized. The steam also helps separate or loosen the fruits (palmas) from the raquis.]

At this point something clever happens. The fruit is separated from the raquis and goes onto further processing. The wasted biomass material left over from the raquis goes to a giant furnace where it is burned. From this they produce the steam used at the plant in addition to generating electricity with a steam turbine. They produce 3.4 MW of power this way (equals 34,000 one hundred Watt light bulbs). The plant uses a lot of this power, and they sell the rest to the national electrical grid. If they had to purchase this electricity it would cost them over $8000 per day!!

The nut is removed from the pulp and the two parts go their separate ways, never to be reunited. There is some crying at this point, and hugging, and taking of pictures with cell phones. But eventually the pulp goes to have its oil extracted and the nut goes on for further processing. The oil that comes out is a mirky orange substance about the color of a pumpkin. It's called crude oil at this point, and goes on to get filtered and sold. After the oil extraction, the leftover solid wastes join their raquis brethren in the furnace to be burned.

[The crude oil is stored in these tanks. The hill on the right has a young plantation that is probably not yet producing fruit. The trees are planted in rows and columns 10 meters apart so that when they are fully grown their canopies will not crowd each other.]

[The nuts after being separated from the pulp]

At this point the nuts are opened and the almonds are removed and crushed to remove the high value palmiste oil. I'm not sure how this is done; I think he said something about an army of ballerinas and Tchiakovsky at Christmas, but I may have missed something in the translation. After the oil is removed from the almond, what remains is a meal sold as feed for chickens and other livestock. The shell from the nut goes to the furnace. Everything is used in one way or another.

[bags of chicken feed being loaded on a truck]

At this point in the process, every bit of the raquis has either been converted into a useful product for sale, or has been sent to the furnace to help generate electricity. But I haven't mentioned one other thing: the liquid wastes. What can be done with the liquid wastes? You guessed it! Make biogas! My favorite subject.

Each ton of fruit combines with water and produces one ton of "mud" which would, normally, be a waste product. But the mud is allowed to cool and sent to one of four underground concrete tanks, each about the size of a football field. They are covered with an air tight, flexible cover which inflates with methane as hosts of methane-producing bacteria digest the amino acids in the "mud".

[a vat of liquid waste "mud" from one of the extraction processes]

[These are the flexible membranes that collect the methane. Although I didn't see any signs, I'm guessing this is a no smoking area.]

[The furnace that burns the solid wastes is about 30 feet tall.]

[Some of the char that comes out of the furnace is reused in the biogas process to help remove unwanted chemicals, specifically H2S and CO2.]

The presence of CO2 in the biogas dilutes the energy content of it, so it's good if it can be removed. The presence of H2S, however, is more sinister. It will mix with water to produce sulfuric acid, a nasty substance you don't want floating around inside your machines because it corrodes their internal parts. After removing these gases, the biogas is largely methane (CH4) and can be burned in generators to produce still more electricity. This is also sold to the national electrical grid. Furthermore, since their electricity production is so green, they earn carbon credits that are sold to Dutch companies who are required (by the Kyoto treaty, I think) to purchase them to offset their own greenhouse gas emissions. Cha-ching in Spanish is cha-chinga. OK, not really.

The Palcasa plant is doing an amazing job at using every scrap of the African Palm to produce renewable energy, multiple useful products, and tons of jobs for the country of Honduras. Other large processors in Honduras are following their example and converting their plants to operate similarly. It's one of the most successful things I have ever seen in Honduras, and it's worthy of emulation and adulation. Oh yes, and it softens hands while you do the dishes.

4 comments:

Very interesting. Thanks for filling us in!

This is a great article! I wish all palm oil plantation used this method. It's great that everything is used in one way or another.

As for palm oil and soapmaking, I only use oils from sustainable palm farms. :)

All I can say is Indeed. Following your short sentence excellent story telling way I like things told.

hahahha

great job for introducing this since today is my second day working in this oil palm + palm oil industry..

keep it up!!

Post a Comment